From 5-Hour Backlogs to 2-Hour Turnarounds: How Mativ Slashed Detention Fees and Accelerated Throughput

Mativ’s Middletown, Del. site faced mounting bottlenecks. Trucks often waited five hours, detention fees soared past $100k annually, and leaders lacked data to push back. The dock team worked hard, but without visibility, they couldn’t scale safely or efficiently.

Specialty Materials Manufacturing | 200 – 300 employees | Middletown, DE

-

Don’t have time to read this? Take it with you!

- Download PDF

90%

lower detention fees

50%

increase in throughput

60%

reduction in backlog

Story overview

Detention fees, safety risks, and bottlenecks limited Mativ’s throughput and strained its dock teams. Five-hour waits and six-figure detention costs piled up with little data to challenge them.

With Rite-Hite ONE, paper logs were replaced by live visibility. Timestamped proof cut detention fees by 90%, real-time insights streamlined workloads, and safety improved. Turnarounds dropped from five to two hours, driving a 50% increase in throughput. In practice, that meant monthly shipping revenue often grew from a $3M baseline to peaks of $6M–$8M.

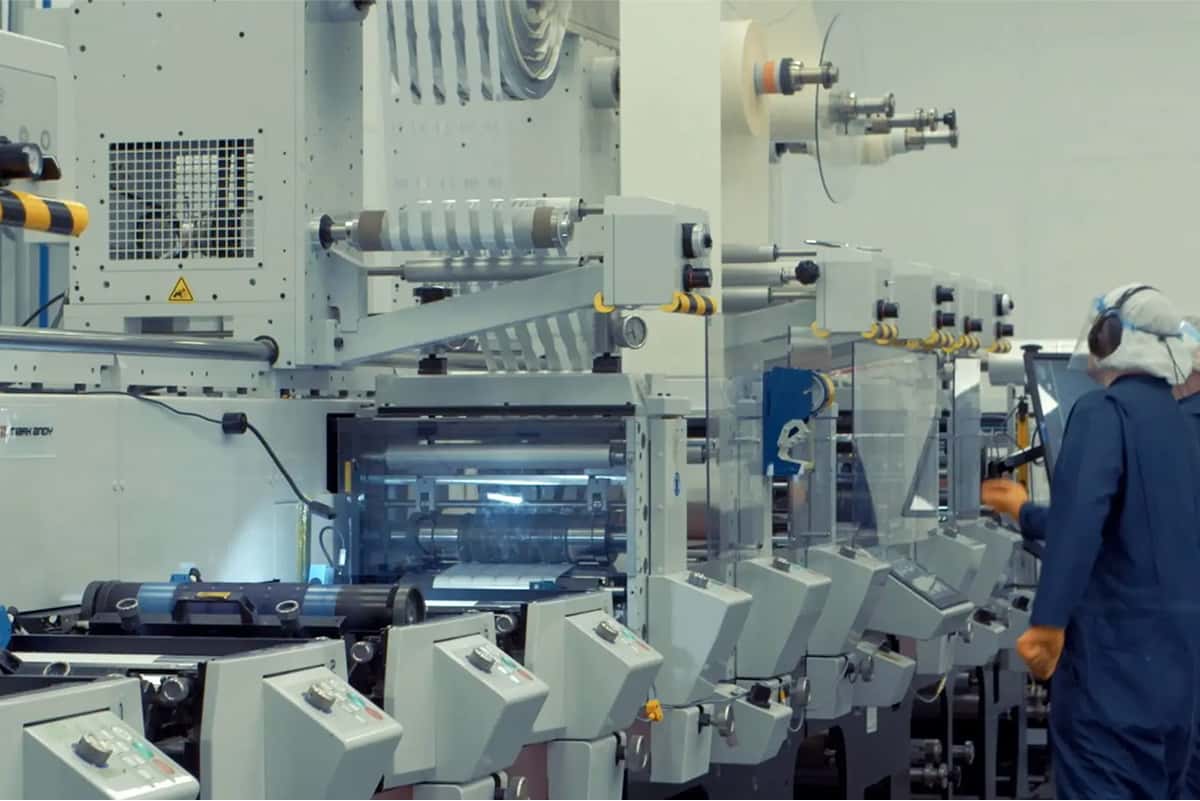

Company Overview

Mativ is a global leader in specialty materials, engineering bold, innovative solutions that connect, protect and purify our world. Headquartered in Alpharetta, Georgia, they manufacture on three continents and generate sales in over 80 countries through a family of business-to-business and consumer product brands.

Use Cases

- Reducing safety risk

- Loading dock shipping/receiving throughput

- Operational efficiency at the loading dock

From 5-Hour Backlogs to 2-Hour Turnarounds

Mativ’s Middletown, Del. site faced mounting bottlenecks. Trucks often waited five hours, detention fees soared past $100k yearly, and leaders lacked data to push back. The dock team worked hard, but without visibility, they couldn’t scale safely or efficiently.

Manual processes couldn’t keep up

With only handwritten logs, Mativ had no reliable timestamps to hold carriers accountable. Utilization patterns were hidden, and the lack of visibility strained both employees and partners.

If a carrier says they’ve been here forever, we have no way to prove it. And if no one’s accountable, that’s a problem waiting to happen.

Data-driven adjustments, on the fly

Shannon’s Rite-Hite representative understood the challenges and suggested Rite-Hite ONE might help. He immediately saw how its real-time visibility could unlock greater efficiency across their loading dock operation.

Today, managers at Mativ rely on the Live Operations View for an uncluttered, nearly real-time picture of every dock position without leaving their desks. That visibility has driven a complete transformation.

“Now we keep Rite-Hite ONE up on our screen. It shows me things I need to see to make the proper changes.”

At the loading dock, teams use Dwell & Detention Analytics to monitor how long trailers have been engaged so they can act before delays become costly downtime. With Asset Lifecycle Tracking, maintenance teams spot wear-and-tear trends early and schedule service before failures occur. And with Utilization Analytics, site leaders gain performance transparency that helps build a culture of accountability and smarter labor allocation.

Greater accountability, safety and efficiency

By connecting dock equipment with timestamped records, Mativ gained the proof it needed to challenge detention fees and improve turnarounds.

- Cut detention fees by 90%, from $100k to $10k per year

- Grew monthly shipping throughput from $3MM to nearly $8MM

- Consistently achieved sub-2-hour trailer turns

The counter at each door tells me when a truck’s been engaged for more time than it should be. Then I can run down and ask what’s taking so long.

The safety culture advanced too. Wheel chocks were replaced with live-monitored restraints, and site-wide performance visibility created stronger accountability. Employees who were apprehensive at first became advocates once they saw the improvements firsthand.

The safety culture also advanced. By replacing wheel chocks with live-monitored restraints and making dock performance visible, Mativ created a safer workplace where accountability became the norm.

A dock transformed

What began as skepticism quickly became buy-in, as employees used the platform to improve their own workflows. Today, Mativ runs faster, safer, and smarter, with the visibility to prove it.

Related Success Stories

Visibility at Every Level: Scaling Safely With Smarter Docks, Zero Compromise

Turning Data Into Action: 44% More Throughput With No Drop in Efficiency

Ready to turn data into action?

Rite-Hite ONE is where safety, uptime and productivity meet. Find out how much you might save with our custom ROI calculator or meet with one of our Rite-Hite ONE facility experts to optimize your operation.