Why Overrides Are the Silent Threat at the Loading Dock

At a busy loading dock, speed often takes priority over safety. Forklift operators rushing to meet tight schedules, new employees not fully trained on equipment, or supervisors eager to keep freight moving, all of these pressures can lead to overrides of dock safety equipment.

On the surface, overrides may look harmless. After all, the equipment is still working, the truck is still being loaded, and no one has been hurt. But the reality is more dangerous. Overrides are a silent threat, quietly bypassing safety systems designed to prevent catastrophic accidents.

What Are Dock Overrides?

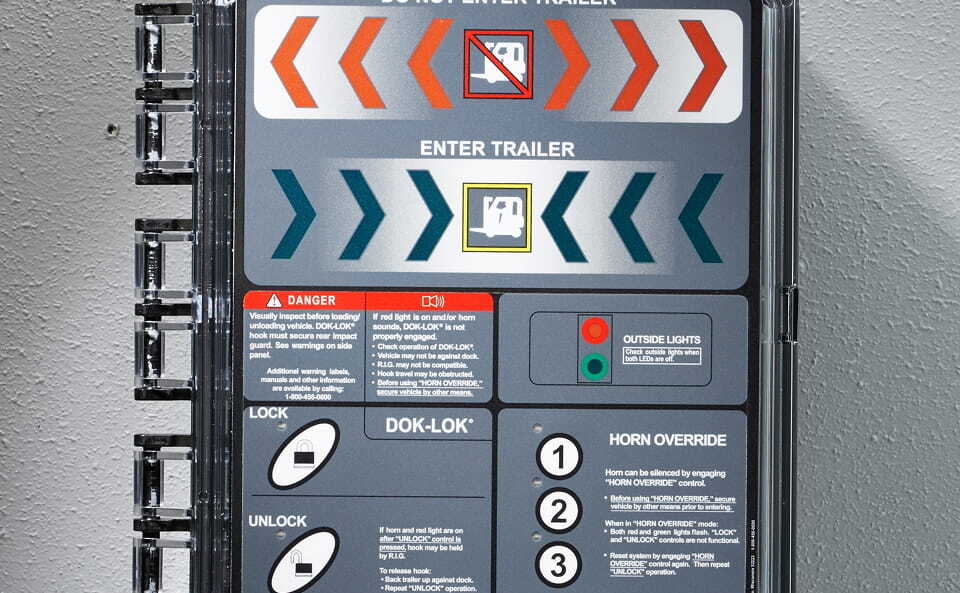

A dock override happens when safety equipment such as vehicle restraints, interlocks, or dock doors is manually bypassed or disabled.

Common examples include:

-

Operators overriding vehicle restraints to begin loading before the trailer is secured

-

Ignoring interlocks designed to prevent dock doors from opening when no trailer is present

-

Manually bypassing alarms or safety locks during maintenance or rush periods

Each override undermines the layered protections built into modern dock systems.

Why Overrides Are So Dangerous

-

Hidden risk accumulation: A single override may not cause an incident, but repeated overrides multiply the risk. One Rite-Hite ONE user discovered double-digit restraint overrides within a single month.

-

Human error under pressure: With turnover and inconsistent training, many operators see overrides as a shortcut to save time, not realizing the risks they are creating.

-

Compliance gaps: OSHA requires adherence to manufacturer instructions. Overrides expose companies to citations, fines, and liability in the event of an incident.

-

False sense of security: Safety equipment appears to be in place, but overrides make those protections ineffective.

Real-World Examples (link to case studies)

-

Union Beer: Rapid growth brought frequent overrides and safety risks. After implementing visibility tools, Union Beer reduced daily overrides by 90%, cutting them from 20–25 per day to just two on average.

-

Mativ: Faced with detention fees and bottlenecks, Mativ also struggled with safety concerns. By replacing manual logs with real-time visibility and monitored restraints, they created a stronger safety culture alongside a 90% reduction in detention fees.

-

Sweet Harvest Foods: When expanding to a larger facility, congestion and unsafe practices grew. By using real-time dock visibility, leaders balanced workloads and cut confusion, boosting throughput 44% without an increase in accidents.

These stories show that overrides are not just a compliance issue, they are a performance and profitability issue too.

The Hidden Costs of Ignoring Overrides

-

Worker safety: Dock accidents can result in severe injury or death

-

Legal and regulatory: Overrides increase OSHA exposure and liability during investigations

-

Downtime and disruption: One incident can stall operations, delaying shipments and straining customer relationships

-

Insurance impact: Frequent safety events drive up premiums and affect EMR scores

How to Prevent Overrides Before They Become Incidents

-

Real-time safety alerts: Monitor and flag overrides the moment they happen so supervisors can intervene

-

Trend analysis: Detect patterns across shifts, docks, or teams to find repeat issues

-

Training reinforcement: Use actual override data in refresher training sessions

-

Clear accountability: Digital logs tie overrides to users and events, ensuring accountability

-

Leadership culture: Leaders must communicate that overrides are not acceptable shortcuts, they are safety risks

Quick Snapshot: Overrides as a Silent Threat

| Factor | Why It Matters | Proactive Fix |

| Hidden overrides | Create risk without being noticed | Live alerts and reporting |

| High turnover | Leads to inconsistent training | Data-driven safety refreshers |

| Compliance risk | OSHA fines and liability | Digital logs for proof |

| Culture of speed | Prioritizes throughput over safety | Leadership enforcement and visibility |

The Bottom Line

Overrides are one of the most overlooked risks at the loading dock. They happen quietly, often out of sight, but carry the potential for severe accidents and costly repercussions.

By making overrides visible through real-time alerts, pattern analysis, and data-driven training, companies like Union Beer, Mativ, and Sweet Harvest have transformed a silent threat into measurable safety improvements.

The safest docks are not just compliant, they are override-free.

Ready to Take Control of Your Dock?

Get the visibility you need to reduce delays, boost throughput and keep things moving no more guesswork, no more fire drills.