Designed for Uptime. Backed by Real Data.

Your maintenance teams need to prevent failures and maximize budgets. Without adding more paperwork to the process. Rite-Hite ONE gives you visibility, automation and insights to simplify complicated work and get the job done with fewer challenges.

Equipment doesn’t warn you before it goes down.

Everywhere you look, your facility presents a challenge. But you can’t manage what you can’t see.

Reactive repairs that already disrupt shipping and operations

Paper-based logs that get lost, skipped, or siloed

No live visibility into cycle counts or equipment stress

Same PM schedules for high- and low-use equipment

Fragmented views of service history across tools and teams

No clear way to prioritize CapEx vs. quick fixes

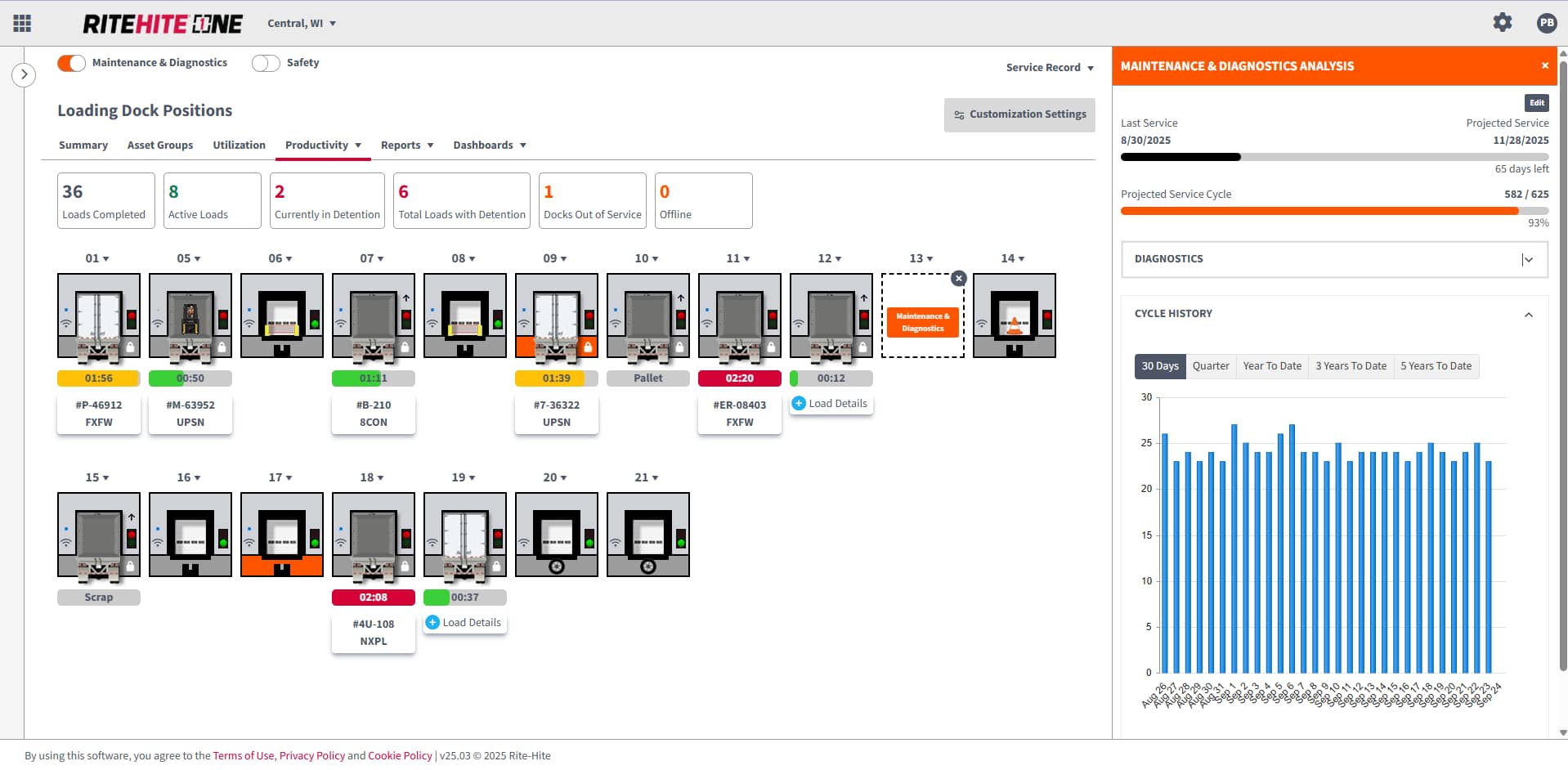

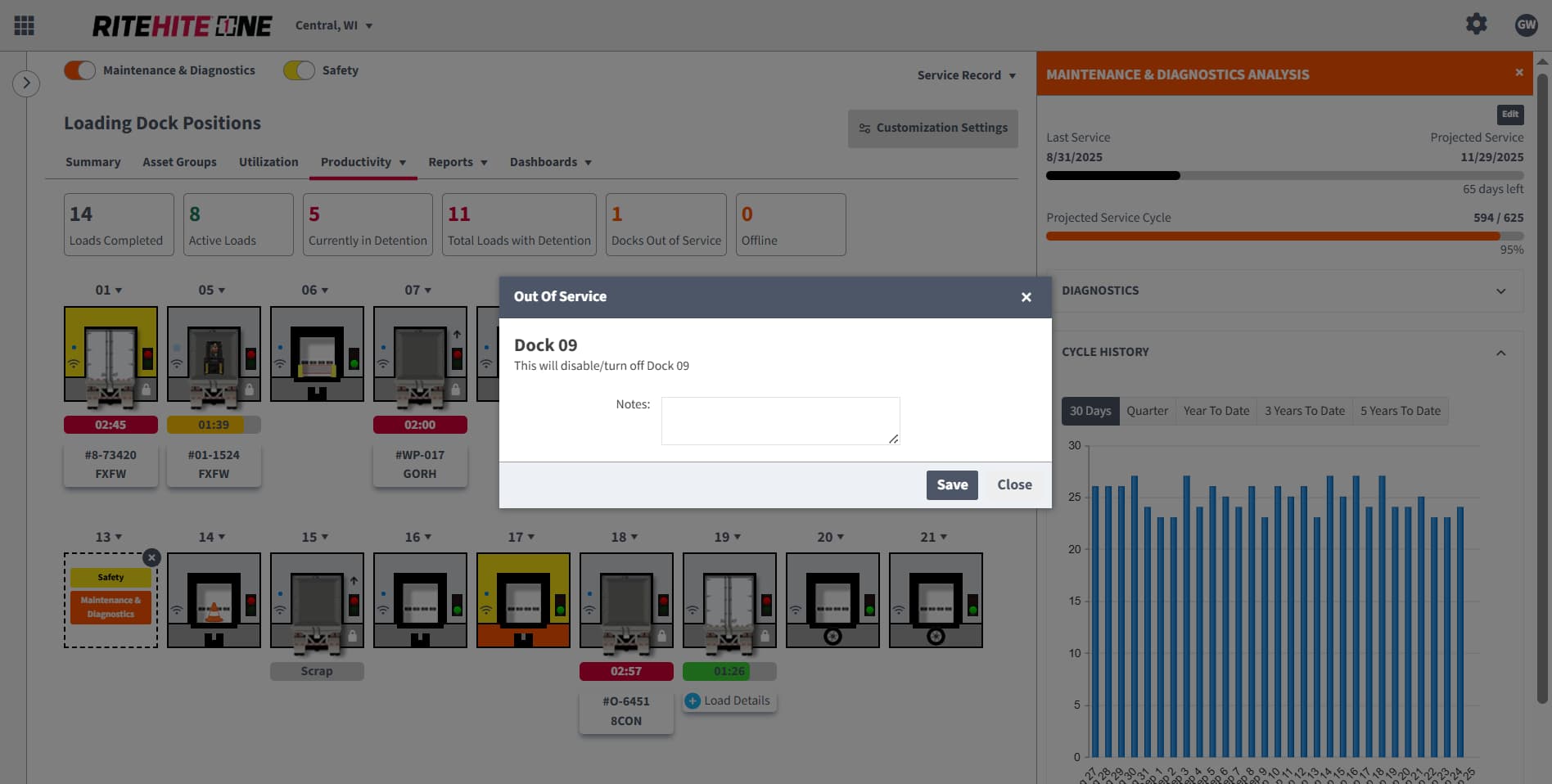

Get Ahead of Equipment Failures with Real-Time Insight.

Ensuring uptime and compliance isn’t optional. And it’s a full-time job. Rite-Hite ONE connects your dock and door equipment to a central system that captures real usage, early failure signals and lifecycle data in nearly real time. It’s how you stop reacting and start getting ahead. From better PM planning to smarter repair decisions, you gain control without added complexity.

Key Benefits

Rite-Hite ONE delivers proactive maintenance insights to help your team reduce downtime, extend equipment life and get the full value of every dollar in your budget.

One Connected View

Consolidate equipment health, usage and service data across sites

Data-Driven Maintenance

Schedule PMs based on real usage, not fixed calendars

Live Cycle Count Monitoring

Spot high-use docks and prevent overwork before failures happen

Smart Budgeting

Use lifecycle trends and service history to prioritize CapEx

Failure Prevention

Get alerts on equipment performance changes before they impact operations

Streamlined Service

Auto-log service events, for visibility into spend and service history.

Maintenance & Uptime

Proactive visibility into health and performance for every dock and door

- Real-Time Cycle Counts

- Preventive Maintenance Scheduling

- Equipment Usage Analytics

- Real-Time Cycle Counts

- Preventive Maintenance Scheduling

- Equipment Usage Analytics

- Asset Health Monitoring

- Integrated Service Logs

- Asset Health Monitoring

- Integrated Service Logs

How It Works

Connect & Integrate Your Equipment

Capture Live Usage and Cycle Data

Get alerts to Trends Before Failures Happen

Plan PM and Budget Smarter

Real Rite-Hite ONE users.

Real time savings.

Dock coordinators manually assigned trucks to doors. But sometimes those doors were already in use. Rite-Hite ONE gave them a centralized live view to smooth out communication.

With Rite-Hite ONE, Union Beer increased its portfolio by 20% with no loss in productivity.

Shipments are more complicated with higher volume and increased SKUs. With Rite-Hite ONE, there’s been no fall-off in throughput.

Frequently Asked Questions

By turning live equipment data (status, errors, usage) into proactive alerts and prioritized work, so you can fix what’s about to fail, not what already did.

Yes. You’ll see high-usage, high-risk assets at a glance, with clear indicators that help you triage and schedule work where it’ll have the biggest impact.

It captures cycle counts and usage trends so PMs are based on actual wear, not calendar guesses, helping you increase PM compliance and extend asset life.

Yes. You can connect existing dock equipment, add new ones as needed, or use the Rite-Hite Connect Device to bring older or third-party equipment online.

You get asset-level performance, downtime history, and spend visibility in one place, making it easier to justify replacements, or extend life with targeted maintenance.

You can configure alerts for thresholds like overrides, abnormal dwell, or error codes. Notifications route to the right people via SMS, the dashboard and email.

By surfacing unsafe sequences/overrides and tying them to specific assets and shifts, so you can address root causes (mechanical or behavioral) and reduce repeat incidents.

Yes. Use facility-wide views and benchmarks to spot outliers, balance workloads, and standardize best practices.

Typical gains come from fewer breakdowns, smarter PMs, and more efficient labor. For a tailored estimate, run the numbers with our ROI Calculator.

Will your maintenance plan scale with your growth?

Get the visibility you need to reduce delays, boost throughput and keep things moving.

No more guesswork. No more fire drills.